Tightening in construction machinery engine repairs is of utmost importance, as the correct fastening of the different components that make up the engine depends on them, ensuring proper functionality. Insufficient tightening can cause vibrations, fluid leaks, and even component breakage, while excessive tightening can damage threads, deform parts, and affect engine operation. Therefore, it is essential to follow the manufacturer's instructions and use the appropriate tools to achieve the correct tightening.

Here are some examples of tightening for the Komatsu SAA6D engine:

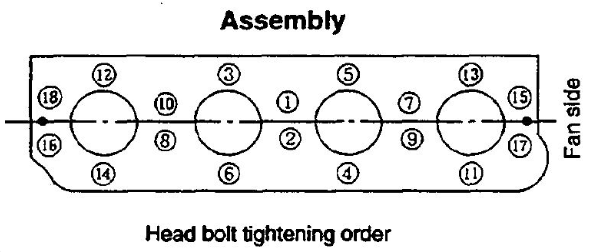

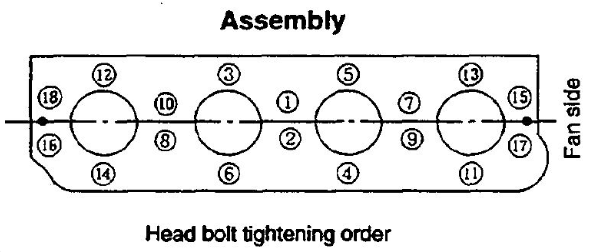

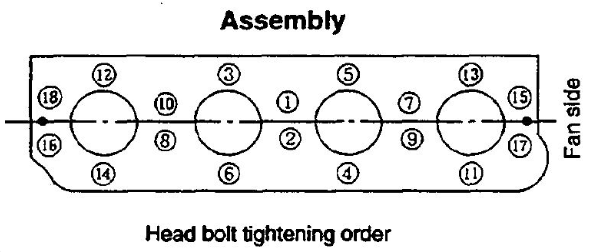

- Cylinder head tightening: The cylinder head tightening consists of three steps, in which the nuts must be tightened as follows: 1) 60 Nm, 2) 90 Nm, 3) Apply an additional 90-degree angular torque.

- Connecting rod tightening: The connecting rod nuts must be tightened to 53 Nm plus an additional 90-degree angle in a clockwise direction.

- Main bearing tightening: The main bearing nuts must be tightened to 150 Nm plus an additional 90-degree angle in a counterclockwise direction.

It is important to remember that these are just examples and that tightening may vary according to the exact specifications of the engine model and the manufacturer's instructions. To achieve the correct tightening, it is advisable to follow the service manual instructions for the specific engine.

At GMotors, we support our regular customers with manufacturer's instructions... so they can set up the perfect tightening!